Development History

TGPRO

About TGPRO

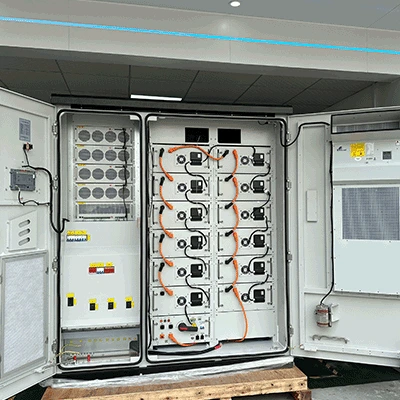

Since the founding of TGPRO New Energy in 2007, we have been leading the forefront in the manufacturing and provision of new energy power systems. As a national high-tech enterprise, we have not only accumulated a wealth of experience, but also brought together expertise in the industry.

As one of the first companies to export Energy Storage System (ESS) products in bulk, we have been providing excellent support and contributing to the development of several energy storage brands. By providing ODM and OEM manufacturing services, we have promoted the dynamic development of the new energy industry.

Our Mission & Vision

Our mission is always technological innovation and the pursuit of excellence.

Our vision is to become a global leader in the energy storage industry, and to provide our customers with more reliable and efficient new energy power systems by continuously promoting technological advances and providing superior products and solutions.

We firmly believe that through our efforts, we will create a broader space for the future development of the new energy industry and help the world move towards a cleaner and more sustainable energy future.

Trusted By The World’s Leading Companies

TGPRO

Warning: Undefined array key "arrows" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 559

Warning: Undefined array key "arrows_tablet" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 567

Warning: Undefined array key "arrows_mobile" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 575

Warning: Undefined array key "normal_arrow_bg_color" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 584

Warning: Undefined array key "hover_arrow_bg_color" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 584

SchneiderElectric

BYD

CATL

AISWEI

ANKE

CHANGHONG

DEYE

EFFEKTA

EVE

GOODWE

GROWATT

INVT

KEHUA

KSTAR

LUXPOWER

MEGAREVO

SERMATEC

SMA

SOFAR

SOLAREDGE

SolarMax

SolaxPower

SOLIS

VICTRON

Voltronk Power

YISHITE

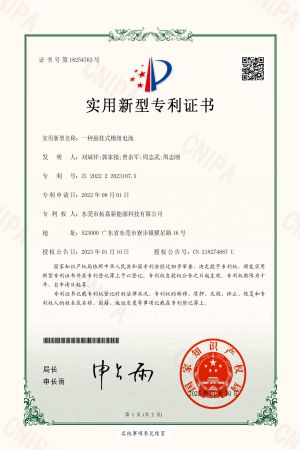

Certification

TGPRO

Warning: Undefined array key "arrows_mobile" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 575

Warning: Undefined array key "normal_arrow_bg_color" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 584

Warning: Undefined array key "hover_arrow_bg_color" in /www/wwwroot/tgpronewenergy.com/wp-content/themes/dt-the7/inc/mods/compatibility/elementor/widget-templates/arrows.php on line 584

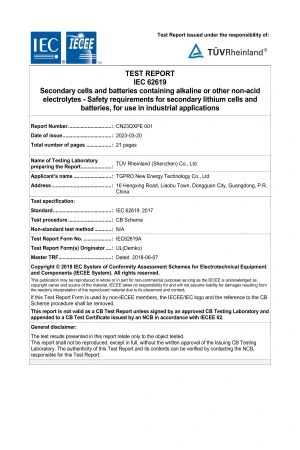

CN23QXPE001Z3

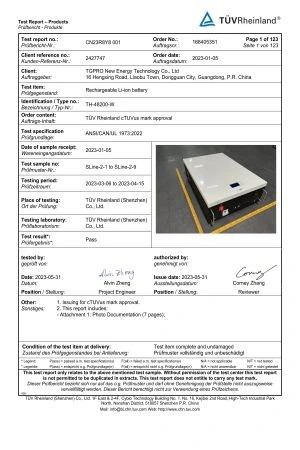

CN23R8Y8 001

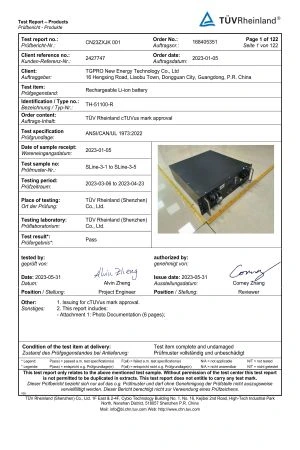

CN23ZXJK 001

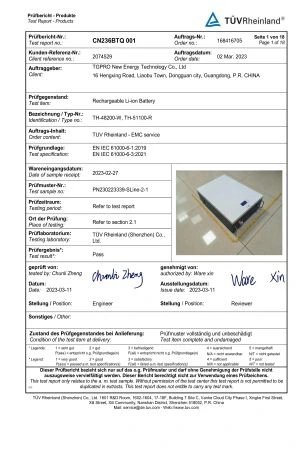

CN236BTQ001TR

JPTUV-145974

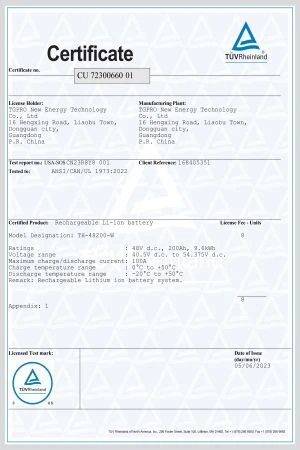

TH-48200-W CN23R8Y8 001 Z3

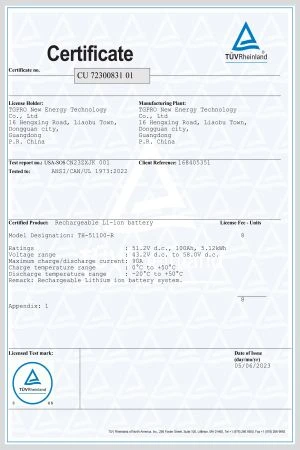

TH-51100-R CN23ZXJK 001 Z3

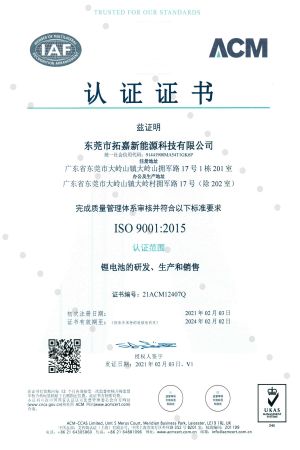

ISO 9001

ISO 9001

ISO 14001

ISO 14001

ISO 45001

ISO 45001

MSDS

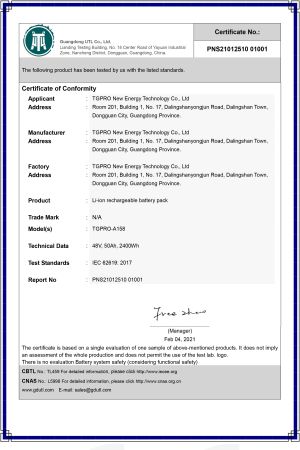

PNS21012510 01001 IEC62619 Certificate

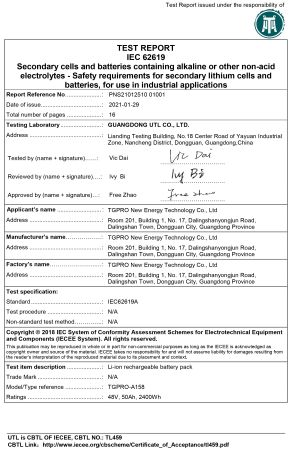

PNS21012510 01001 IEC62619 Report

UN

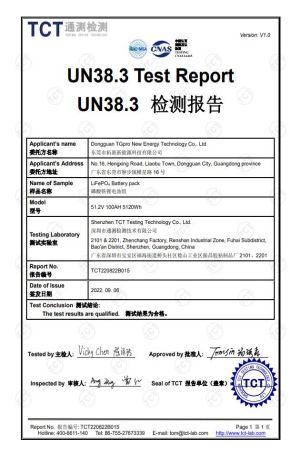

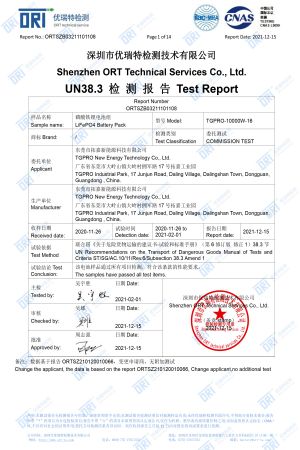

UN38.3

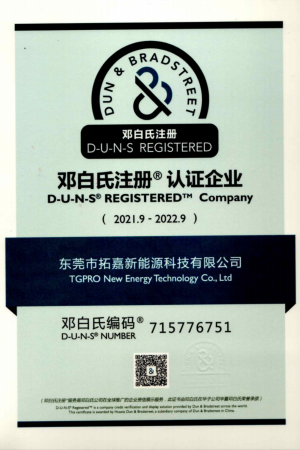

D-U-N-S

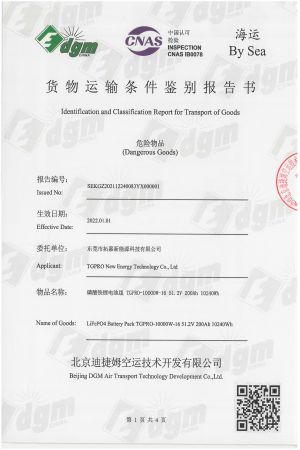

Shipping report

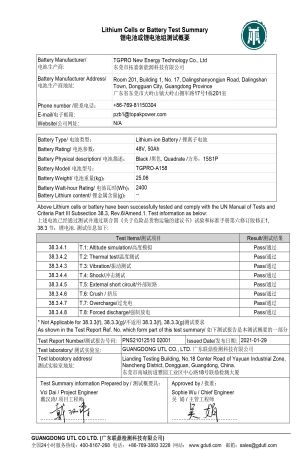

Lithium battery pack test summary

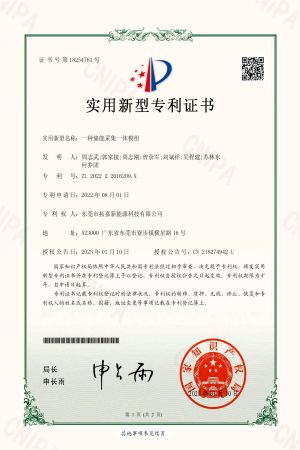

Certificate

Certificate

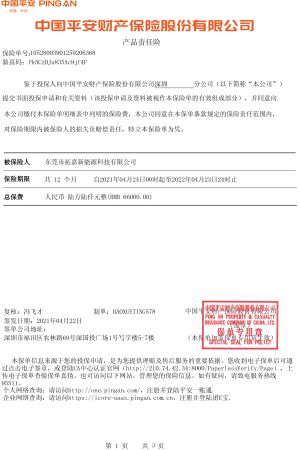

Insurance

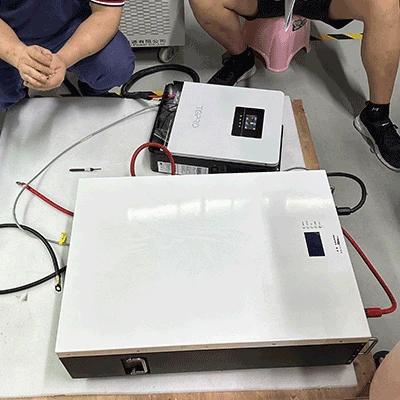

Production Process

TGPRO

R&D

Cell Matching

As part of quality control, each cell is measured and segregated into categories according to their capacity levels.

Terminal Connection

Assembly

BMS Testing

Aging & Testing

Contact us

+86 18025286937

Just Call With Us

info@tgpronewenergy.com

Just Emai With Us

APPOINTMENT